Roller crushers are designed for crushing both wet and dry laboratory samples with hardness less than 6 in Mohs scale. We offer crushers with two or four rolls. Both types of crushers are available in versions with regulated gap between rollers (type R) to allow changing final grain size.

Typical crushed materials are: construction materials, coal, ores, minerals, glass, soil.

Roller crushers are mostly used in sampling systems for loose materials.

Roller crushers are designed for crushing both wet and dry laboratory samples with hardness less than 6 in the Mohs scale.

The sample is crushed between two rotating steel rollers. Run-through crushing.

- possible manual or fluent (using electric geared motor) adjustment of roller gap

- step regulation of roller gap

- grinding elements hardness: 50HRC

coal, ores, minerals, slag, glass, sinters, fluxes, soils, seeds, clinker, fertilizers, ashes, dusts, residues, coke, dolomite

| Crusher Model | Dimensions | Weight | Power supply | Power consumption | Allowed sample humidity | Preliminary grain | Final grain (depending on the gap adjustment) | Roller material | Efficiency (depending on the gap adjustment) |

|---|---|---|---|---|---|---|---|---|---|

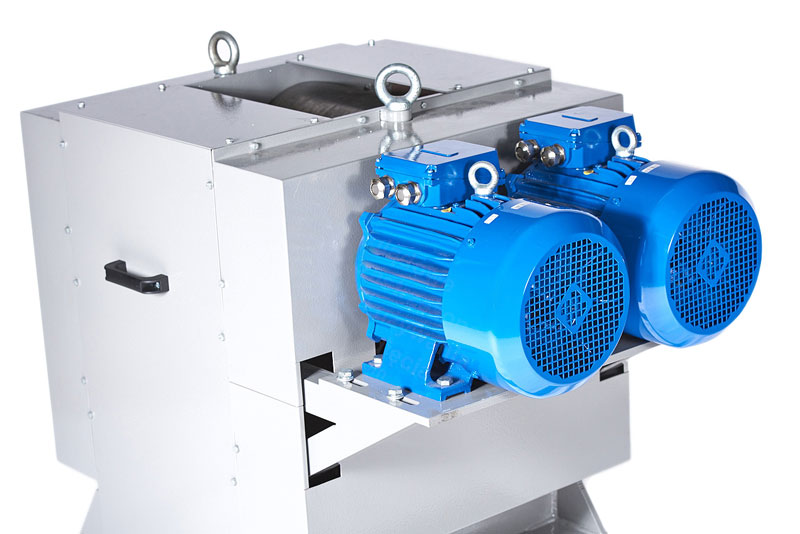

| LKW-2 | 1350x600x380mm | 450kg | 400V | 6kW (2x3kW) | <20% | <40mm | No adjustment approx. 1mm | Hard-faced steel | max 100kg/h |

| LKW2-R | 1000x700x1000mm | 250kg | 400V | 6kW (2x3kW) | <20% | <40mm | from 1 to 20mm | Hard-faced steel | max 100kg/h |

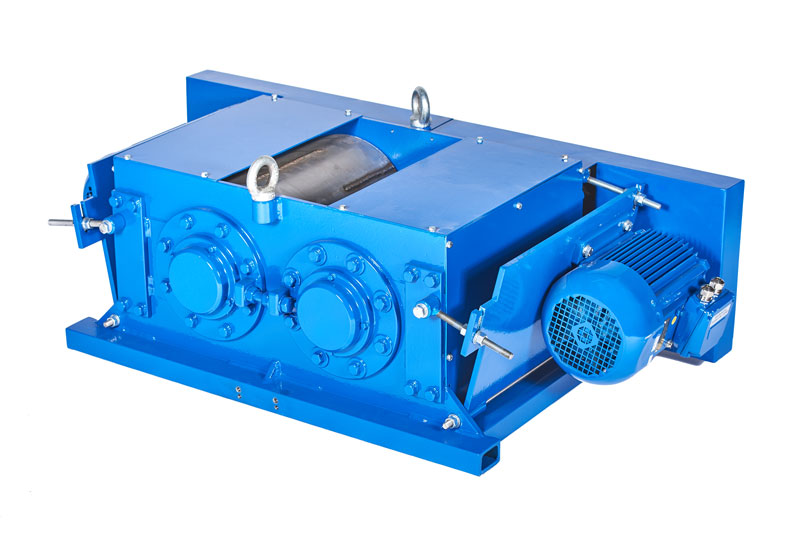

| LKW4 | 1200x1070x1100mm | 650kg | 400V | 11kW (2x5,5kW) | <15% | <60mm | No adjustment <3mm | Hard-faced steel | max 350kg/h |

| LKW4-R | 1200x1070x1100mm | 650kg | 400V | 11kW (2x5,5kW) | <15% | <60mm | Upper rollers from 4 to 14mm lower rollers from 0 to 8mm | Hard-faced steel | max 350kg/h |