Vibratory grinders are used for grinding and simultaneous blending dry laboratory samples. Vibratory grinders are the most popular and most versatile devices sold by our company. They are intended for the final grinding and blending various dry laboratory samples having hardness of less than 9 in the Mohs scale, using a tungsten carbide grinding vessel. Using these mills, we can get the final particle size less than 20 microns in a very short time (see below for details).

Typical materials grinded in these mills are coal, ores and minerals.

- dust-free, contamination-free (Cd, Cu, Ca, Cr, Mg, Ni, Hg, P)

- easy and quick closing

- capacity for grinding suspension samples

- easy grinding vessel substitution thanks to low weight (LMW-s and LMW-4)

- final grain depends on the grinding time

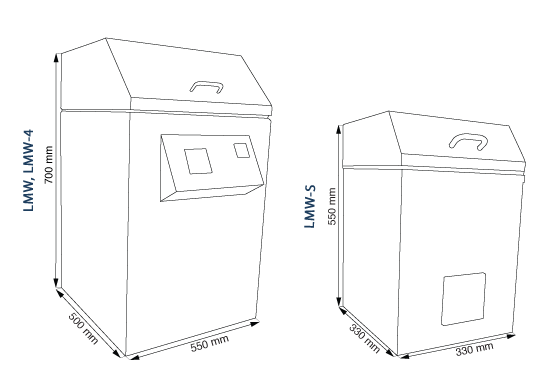

Grinder model Dimensions Weight Power supply Power consumption Grinding time Preliminary grain Final grain Effective grinding vessel volume Grinding vessel material LMW 500x600x920mm 120kg 400V 0,8kW from 1s to 100 min. 10mm 20µm 250ml, 100ml Steel, tungsten carbide LMW-S 330x330x550mm 50kg 230V 0,25kW from 1s to 100 min. 10mm 20µm 30ml Steel, tungsten carbide, corundum, zirconium dioxide Samples prepared in the vibratory mills are widely used in laboratories in heavy industry, mining processing of minerals and energy. Particulary in spectrometry and X-ray diffractometry, infrared analysis, AAS carbon and sulfur analyzers.

Depending on characteristics of the sample, grinding vessel and grinding parts can be made of several types of materials:

- hardened steel (65 HRC),

- stainless steel (48 HRC),

- tungsten carbide (9,5 Mohs),

- corundum (9 Mohs),

- zirconium dioxide (8,5 Mohs).

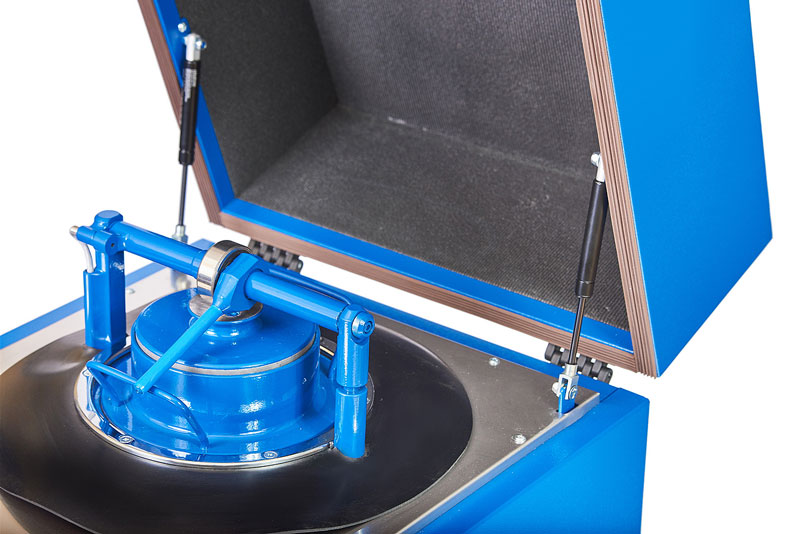

- The electric motor moves the unbalanced rotating element and produces vibrations in the horizontal plane. The vibrations are transferred to the grinding vessel, where the sample is grinded between the walls and movable elements.