Application

Quern grinders are designed for grinding intermediately wet and dry laboratory samples having a hardness of less than 8 in the Mohs scale (using tungsten carbide quern) or less than 65 HRC (using steel quern). After grinding, the end grain’s radius is less than 0.5mm. End grain control is done by adjusting the width of the gap between quern (regulation between 15 and 0,5mm. The width of the set slot is displayed on digital display.

Typical sample materials:

- coal

- ores

- minerals

- fluxes

- glass

- sinters

- cinders

- soils

- grain

- plants

- aches

- cement

- fertilizers

- residues

- coke

- dolomite

- flexible, mechanic adjustment of the gap between querns with a digital display (10-0,5mm)

- steel receiving container about 3l

- easy and fast closing

- dust-free thanks to closed end-material container

The sample material is ground continuously between two querns one of which is in motion, the other is fixed.

Quern grinders

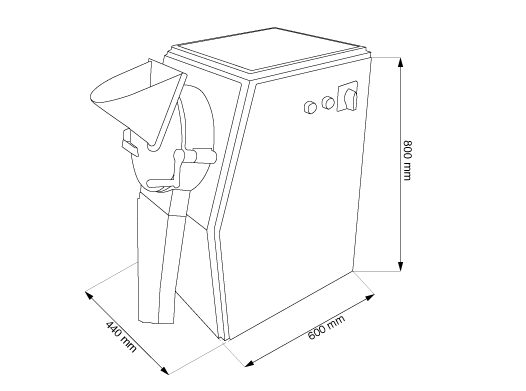

| Grinder model | Dimensions | Weight | Power supply | Power consumption | Preliminary grain | Final grain | Quern Material | Efficiency | Allowed humidity level |

|---|---|---|---|---|---|---|---|---|---|

| LMŻ | 500x600x900mm | 120kg | 400V | 1,5kW | <40mm | <0,5mm | tungsten carbide, steel | Depending on the gap setup approx. 100kg/h | <15% |