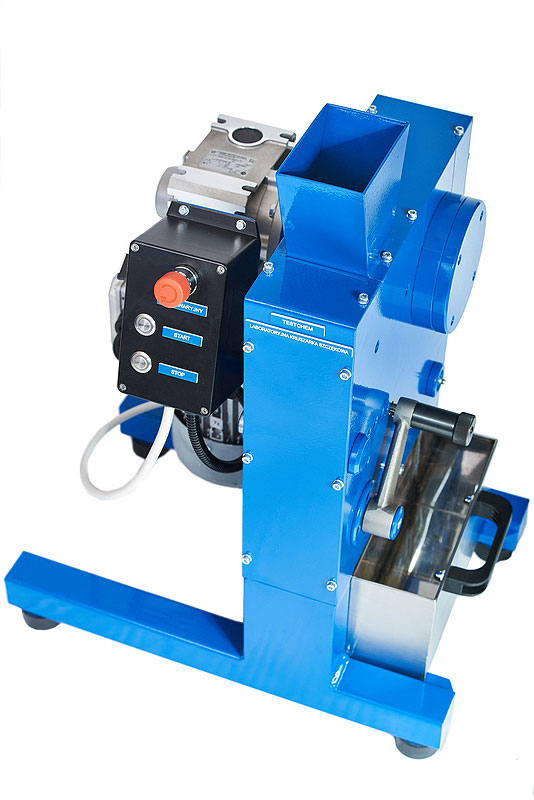

The crusher is used for preparatory grinding of dry and hard materials.

- material entrance: lockable

- jaw gap adjustment

- material collection to a locked container

The material is inserted between two jaws: mobile and fixed. Reciprocating motion of the jaw moves the material downward, towards the narrowing gap between the jaws.

coal, ores, ferroalloys, slag, glass frits, fluxes, soil, clinker, cement, fertilizers, dust, sludge, coke, dolomite

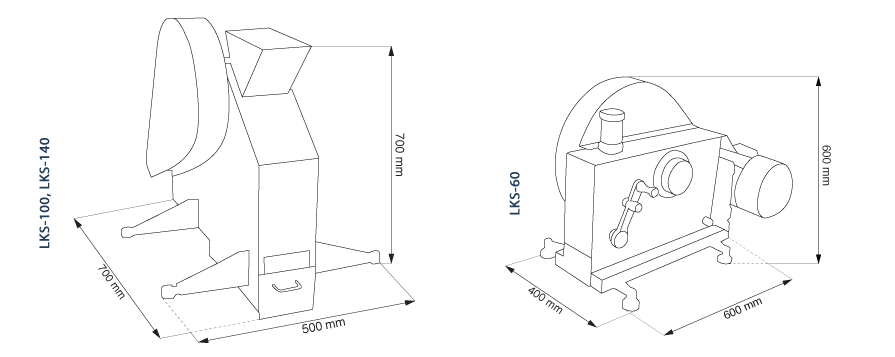

| Crusher Model | Dimensions | Weight | Power supply | Power consumption | Allowed humidity | Preliminary grain | Final grain (depending on the gap adjustment) | Jaw material | Efficiency (depending on the gap adjustment) |

|---|---|---|---|---|---|---|---|---|---|

| LKS-60 | 400x540x570mm | 65kg | 400V | 1,1kW | <5% | <60mm | from 1 to 7mm | steel, tungsten carbide | max 50kg/h |

| LKS-100 | 970x820x990mm | 410kg | 400V | 3kW | <5% | <100mm | from 1 to 10mm | steel | max 130kg/h |

| LKS-140 | 970x820x990mm | 480kg | 400V | 3kW | <5% | <140mm | from 3 to 20mm | steel | max 200kg/h |